POTASH MINING

—Michigan Potash has chosen a site wholly unsuited for solution-mining, an area consisting of several small uneven patches of both high and low ground, sloping off on all sides into the headwaters of 4 creek systems along with their associated lakes and wetlands. All of these drain into the Muskegon River approximately 4 miles away. Most concerning is the proximity to, and drainage into Bullkill Marsh.

—Shallow groundwater flows throughout this area are complex and as-yet unmapped. They feed an untold number of seeps, springs, creeks, and wetlands. Launching a solution-mining operation over such terrain would never be attempted by an experienced mining company, intent on avoiding environmental harm. Doing so without first mapping and understanding these flows is incomprehensibly reckless.

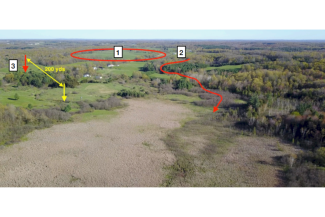

[1] Refinery, storage, & shipping site: The refinery and storage facilities would be located in this high-ground area, along with facilities to handle 200 large trucks per day. It’s highly questionable whether the site is large enough to accommodate such activity. (The PPG/Mosaic/Cargill site comprises 520 acres, more than three times the 162 acres owned by Michigan Potash, half of which is either too hilly or too wet.) Most surrounding terrain appears to be unsuitable for future expansion. [2] Waste-well site: A single waste-well and attendant facilities is to be situated behind these trees. It is to be perched on the edge of a steep ravine which drains directly into Bullkill Marsh along the route shown. Brine spills here would likely contaminate the headwaters of Bullkill Creek. [3] The "Gray" site: A cluster of 8 production-wells & 2 waste-wells, along with all of the connected pumps, pipelines, valves, tanks, etc. is to be located just beyond this grove of pines, approximately 200 yards from the edge of the marsh. This the most concerning of all their decisions to-date. (see section labelled “Gray Site”).

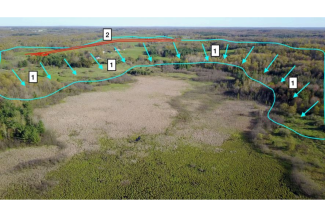

- Although much of Michigan Potash's site drains into Bullkill Marsh, it also drains into three other creek systems. This view shows the adjoining terrain to the east, which flows into the Big Stone Creek System (incl. Big Stone Lake & Lake Miramichi). The entire area is riddled with shallow aquifers, springs, seeps, ponds, and wetlands (crosshatched areas) and functions like a large sponge, constantly pouring its contents into that system.

- The Michigan Potash site drains directly into Bullkill Marsh to the northwest, Big Stone Lake and Creek system to the east, Maney Lake & creek to the North, and Pogy Creek to the south. Surface drainage occurs over fairly steep terrain into wetlands in close proximity to the site. Drainage occurs both above- and below-ground, throughout an area containing a multitude of shallow, unprotected aquifers, seeps, springs, wetlands, creeks, and lakes. To our knowledge, none of these surface or sub-surface features have been explored or mapped by Michigan Potash, either beneath their site or around it.

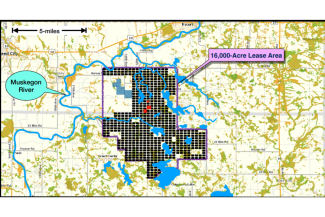

If Michigan Potash ever realizes their dream of producing a million tons of potash per year, the map below gives an idea of what that would mean for the environment 40 years from now:

Each black rectangle portrays a mining cavity. Over the years, all of these cavities will be connected by high-pressure pipelines transporting corrosive brine solutions to and from a centralized refinery. In the course of its lifetime, this vast array of pipes, valves, pumps, filters, & tanks will experience a multitude of leaks & spills. Such is the nature of solution-mining. No plant or animal in this area can survive prolonged contact with those brines.

The operation is meant to continue expanding for 110 years beyond this.

Potash Mining Home

Solution-Mining Basics

History of POTASH Mining

Economics

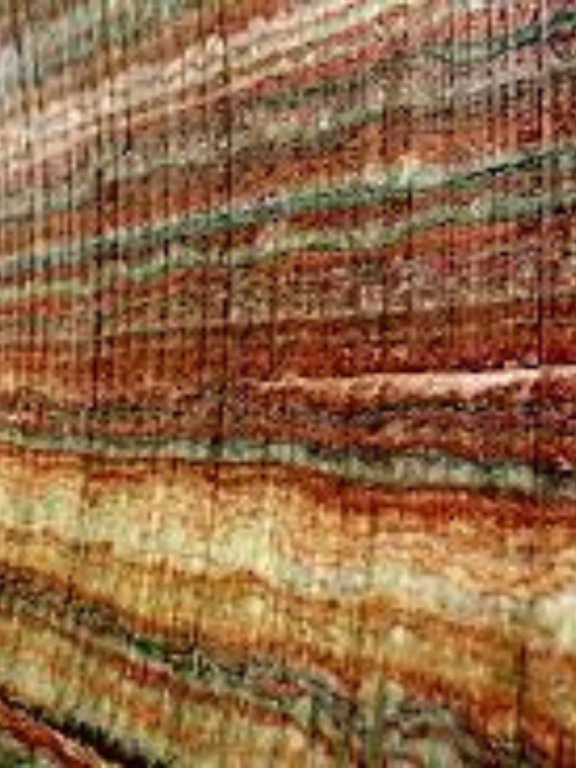

The "Ore" Body

Water Withdrawal

Well-spacing, Pipelines, & Sprawling

Terrain, Sites, & Brine

Gray Site